We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Throughout the season, Swiftune offers ready advice on keeping your engine in peak condition; Nick Swift is also on-hand at many of the historic meetings. Mid-season exploratory checks, dyno sessions, ‘freshen-ups’ and full rebuilds are the key to the performance of the engine. We are always pleased to take on evaluation of your existing race engine for rebuilding or upgrading.

We can do all this...

- Rebuild your existing Swiftune competition engine, meeting the needs of the ‘next race’ deadline.

- Swiftune can evaluate your non-Swiftune engine if you are dogged by poor reliability or performance.

- Build new competition engines and transmissions with components selected to meet your requirements.

Our Services

Engine and Transmission

Keeping race engines at the peak of their performance means regular rebuilds and Swiftune will always ensure you get ‘out’ for your next race whatever it takes. Every rebuilt engine goes on the dyno for running-in and final tuning so you will take to the grid knowing your engine is truly as good as new

Competition engines and transmissions

When only winning is good enough, racers beat a path to Swiftune’s door for a brand new engine and transmission. Utilising our extensive experience, every component, from crankshaft to pistons to camshaft profile, is selected to meet your requirements. You can trust us; we know what gives results.

Evaluation

Get the feeling you no longer have the fastest engine around or you are dogged by poor reliability then we can look at your engine, whatever its origin, evaluate it, make suggestions for improvements that meet your budget and then re-build it for you – the next best thing to a brand new Swiftune engine or transmission.

Competition Engines

In Historic Touring Car racing, Mini’s have gone from strength to strength thanks to the crowd-pleasing ‘David and Goliath’ acts performed at every round against the mighty Cortinas and Mustangs.

The increasingly popular Mini Cooper S can be seen competing now at most major European classic races at some of the most iconic tracks including Spa, Silverstone, Nurburgring and Goodwood and in popular race series’ and events such as Masters, U2TC, HSCC and The Goodwood Revival. Power is king for an FIA Mini yet the need to use twin SU carburettors and points ignition doesn’t make life easy. Hence Swiftune focuses its detailed development work on the cylinder head and camshaft.

At the heart of this development programme is our FIA approved Swiftune new cylinder head casting with CNC porting programmes. Just as important is Swiftune’s partnership with Kent Cams for race-proven camshaft design because matching the cam and head characteristics is critical to achieve those last few bhp.

Add Swiftune’s 50 years’ experience of building competition A Series engines and you won’t be surprised that the 1293cc engine is now producing over 125bhp at 8000rpm. The essential race reliability comes from the use of high grade components and years of experience applied to the all-important hand assembly process.

Swiftune’s race winning engines have been proven at many historic race meetings including the iconic Goodwood Revival which has seen a Swiftune Mini win the class every time since 2009 and most recently saw the top 4 Mini’s in the St Mary’s Race in 2015 all Swiftune.

Being one of the most popular single seater championships in historic racing, the Formula Junior cars can be seen putting on a great show at some of the most iconic circuits and meetings, including the Goodwood Revival and Monaco Historic Grand Prix.

Swiftune has specialised in this formula for several decades but most recently in the 2015 season Swiftune powered cars have been victorious in the European Lurani Trophy, HSCC Front Engined and Silverline Championships, taking overall championship victory and class wins.

Swiftune concentrates on improving reliability while also raising power output in what is a very competitive series where every bhp counts. High grade components, including steel billet crankshaft and superior rods and the latest high tensile steel bolts are used and together with very careful assembly the result has given the most competitive and reliable A Series Engine options.

Race

For 50 years we have been building A Series competition engines for a wide variety of championships all over the world. Whether its competitive rallying to track racing, we are able to bespoke build an engine to the exact regulations of the championship without sacrificing the Swiftune power that will lead you to victory!

Today we are currently successfully powering three Metro Turbos, 1275 GT Longman and Mowatt Replica Mini’s which both feature at Goodwood and also powering race and championship winning Mini Miglias. We are able to undertake any build whether you are looking to compete in Mini 7, CSCC, HSCC, Autotest to hillclimb. No build is impossible!

Road

Our bespoke road engine builds range from Classic engine restoration for cooper S, MK1 and Mk2 Minis, to Street/Track-Day warriors and we have also done engine restoration for ex-Works Rally cars. Engine sizes range from 850cc through to 1600cc.

The rising popularity of historic rallying in the UK and the revival of famous pan-European classic rallies has given many enthusiasts the chance to get behind the wheel of a Mini Cooper S and relive the glory days of Hopkirk and Makinen.

Swiftune’s 50 years of experience tuning the A series engine means it is perfectly placed to produce rally power trains which deliver great driveability and superb reliability.

- Nick Swift explains: “A wide spread of power is essential for rallying Minis which makes the camshaft selection and the cylinder head porting critical.” By increasing the air speed in the inlet tract and port, throttle response and torque improves – exactly what is needed for the inherently unpredictable nature of rallying driving.

Historic rally team, Soderqvist have successfully campaigned their original 1965 Rally Cooper S throughout the Swedish rally season. The highlight of the year competing in the WRC Swedish Rally event and for the last three years winning the 1300 class in the gruelling event.

Technical Notes

Please read this instruction carefully. An incorrect installation can destroy the CSI and/or damage the engine! In case of any doubt, please consult an expert. Watch out for high voltage!

Installation:

- Check the resistor value of the ignition coil. For 12 volt ignition coil more than 2.5 ohm. If the resistor value is too low it can cause overheating and/or damage the CSI. It is recommended that you use a Lucas DLB 105.

- It is recommended to use HT silicon leads (with resistance of at least 2 K ohm). If you want to use copper leads, always use resistor spark plugs (with resistance of at least 2 K ohm).

- With the existing distributor still in place set the static adjustment of the existing distributor at 0 degrees TDC, using the original timing marks from flywheel or crankshaft pulley, making sure that the rotor arm points to the number one spark plug. For a further check that the engine is at TDC on number one cylinder you will be able to insert feeler gauges for both valves (see photo).0542, 0505

- Remove the old distributor. The drive key is offset. Ensure that the larger section is to the top (see photo). 0521

- Disconnect all wires of the ignition coil. Determine the 12 volt power supply wire and connect it to the + contact of the ignition coil together with the RED wire of the CSI. Do not connect the wires yet. If the 12 volt supply is connected directly to the black wire the distributor will not work and may be irreparably damaged!

- Turn the ignition on. 0523

- Turn the CSI to the left until the led flashes; the number of times that the led flashed is the curve number that it is currently set to.0529, 0531

- Adjust with the help of a small Philips screwdriver to the right curve (see table). 0546

- Slowly turn the CSI distributor to the right (clockwise) until the blue led lights continuously. The CSI is now adjusted to the static adjustment point. Tighten the CSI.0537

- Turn off the ignition and connect the black wire to the negative contact of the ignition coil.

- Assemble the distributor cap and connect the ignition cable, watch the order and keep the high voltage cables as far away as possible from the other cables (to prevent interference).0538

- Put the car into neutral and start the engine.

- If you are using a tachometer, this can now also be connected to the black wire.

- Check the adjustment with the help of a stroboscope and check that it is set on 10 degrees.

- If you want to change the curve number, turn the ignition on, (don’t start the engine) and remove the cap – you will see the led light flashing. If the led light doesn’t flash, crank the engine a little bit until the led light flashes. Select with the help of a small Philips screw driver, the right curve.

Gear Kit Ratios

| 1st | 2nd | 3rd | 4th | |

| 2.1 Kit | 2.143 | 1.486 | 1.193 | 1.1 |

| 2.3 Kit | 2.362 | 1.564 | 1.193 | 1.1 |

| US Kit | 1.692 | 1.441 | 1.197 | 1.1 |

Crown Wheel & Pinion

| C/W | PINION | RATIO 1:1 | RATIO 1.043 | RATIO 1.087 | |

| 3.4 | 71 | 21 | 3.381 | 3.526 | 3.675 |

| 3.7 | 56 | 15 | 3.733 | 3.894 | 4.058 |

| 3.9 | 55 | 14 | 3.929 | 4.098 | 4.271 |

| 4.2 | 55 | 13 | 4.231 | 4.413 | 4.599 |

| 4.5 | 63 | 14 | 4.5 | 4.694 | 4.892 |

| 4.7 | 75 | 16 | 4.688 | 4.890 | 5.096 |

What is an ATB Helical LSD differential?

The Automatic Torque Biasing Helical LSD differential, developed and patented by Quaife, provides smooth, constant traction for racing or slippery road conditions. It is ideal for Minis because it has no adverse effect on the steering of a front wheel drive vehicle so combating FWD torque steer and understeer.

The ULTIMATE Differential

The Automatic Torque Biasing Helical LSD Differential enables your Mini to accelerate quicker and corner faster. How? Simply by getting the power to the ground!

The Swiftune differential powers both drive wheels under nearly all conditions, instead of just one wheel. With a normal open differential much precious power is wasted through wheel spin under acceleration. This happens because the open differential shifts power to the wheel with less grip – along the path of least resistance.

The Quaife differential, however, does just the opposite. It senses which wheel has the better grip, and automatically biases the power to that wheel. It does this smoothly and constantly, and without ever completely removing power from the other wheel.

In cornering, while accelerating out of a turn, the ATB diff biases greater power to the outside wheel, reducing inside-wheel spin. This allows the driver to begin accelerating earlier, exiting the corner at a higher speed.Save & Exit

The Swiftune differential also controls loss of traction when the drive wheels are on slippery surfaces such as ice and snow or mud, providing the appropriate biased traction needed to overcome these adverse conditions. The drive is both constant and infinitely variable drive. Power is transferred automatically without the use of normal friction pads or plates seen in other limited-slip designs.

The ATB Helical LSD differential’s unique design offers maximum traction, improves handling by reducing understeer, curbing steering ‘fight’and puts the power where it is needed most. A definite advantage, whether you are on the track or on the street.

The ATB differential is extremely strong and durable, and since it is gear-operated, it has no plates or clutches that can wear out and need costly and regular replacement. There is no maintenance required to the unit, so once installed the unit can be forgotten, apart from the better road responses.

The Swiftune ATB differential is great for performance or track day Minis, racing or rallying. Racers don’t have to put up with locking mechanisms or spools that tear the steering wheel out of their hands when cornering. Because it behaves like an open differential during ordinary driving, street drivers will have trouble telling it’s there until pushing the cars towards its limits.

The Quaife ATB differential is proven in everything from SCCA Rallying to drag racing and Formula 1. It provides autocrossers with such an advantage, it has become “required” equipment for a winning effort.

Swiftune has exclusive rights to the Quaife patented ATB diff for Minis.

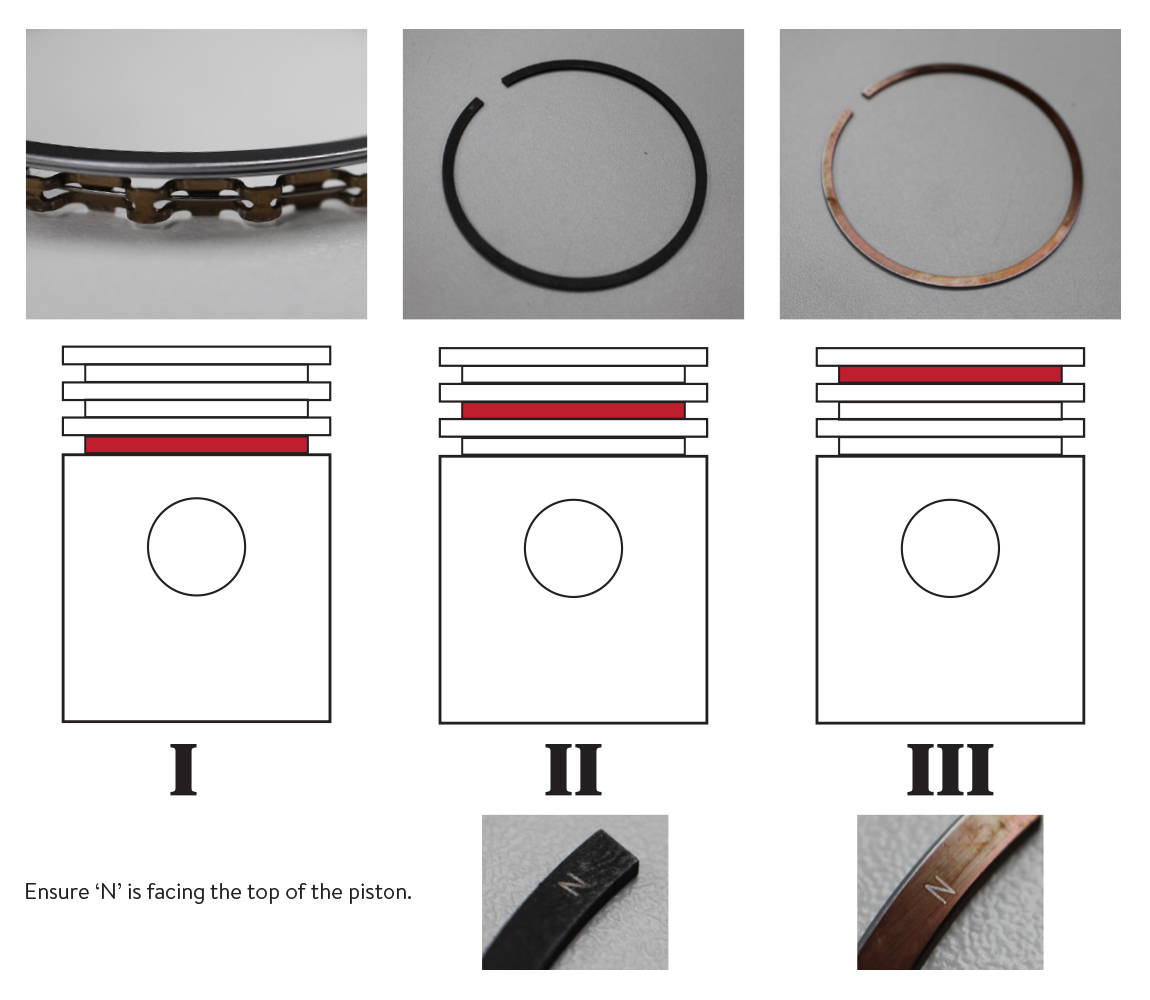

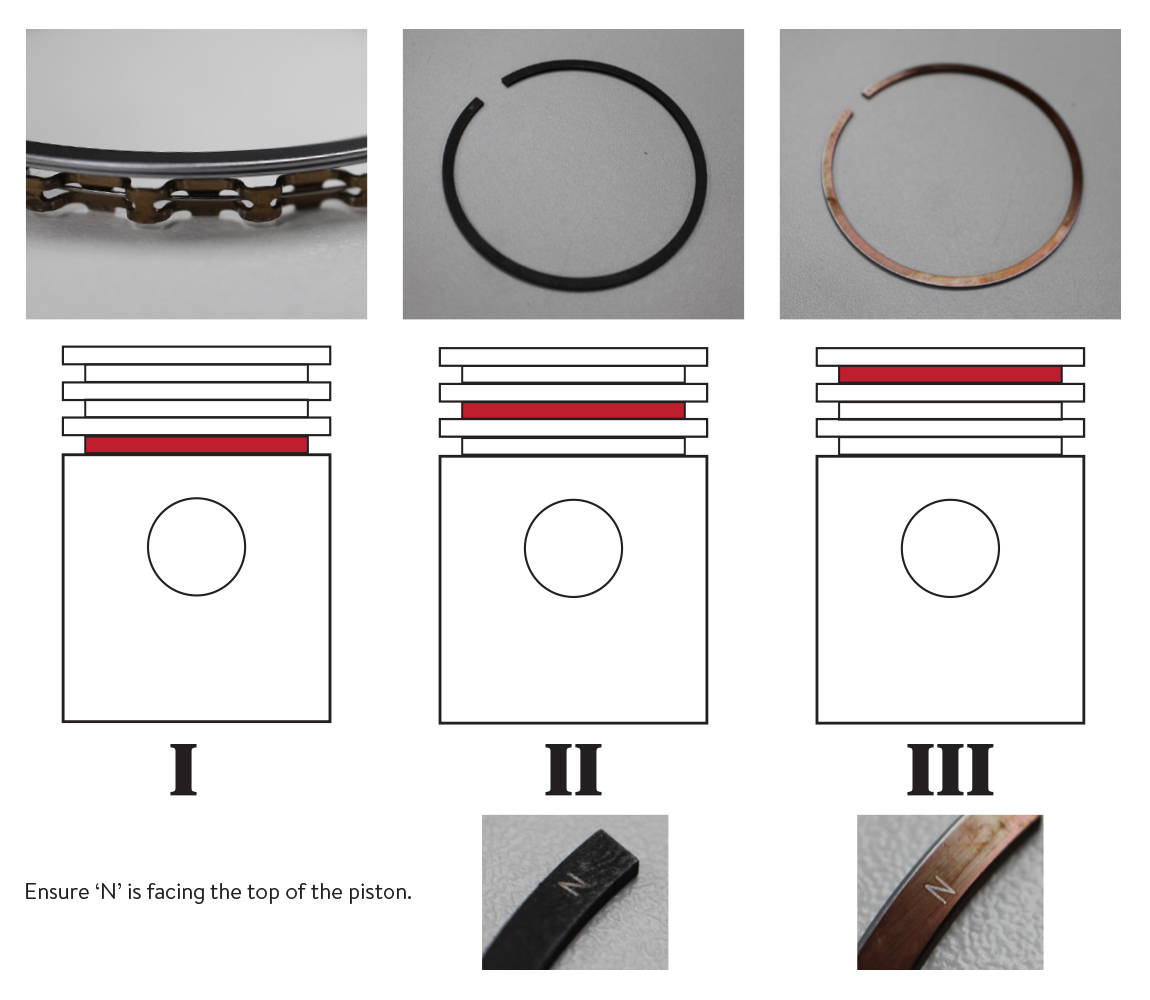

Heritage Die Cast Pistons - Fitting Guide

Installation:

- The ideal running clearance is calculated at 0.0025”

- When honing to achieve your final bore size. It is recommended that at least 0.002 to 0.003” is removed in the honing process using M3F finishing stones.

- These pistons have been picked to be within 2 grams of balance but can be balanced to tighter

- tolerances if required.

- Make sure they are thoroughly washed. A final wash should be with the pins installed into the pistons. This will enable the pins to be free moving before press fitting onto con rods.

- Pistons will need to be interference/press fitted by a professional

- Piston rings need to be carefully washed and then assembled onto the pistons. See piston ring

- fitting guide for which groove each ring should be installed in.

- Make sure the piston ring gaps are equidistant apart.

- It is recommended that you use the Swiftune installation tool rather than a ring clamp device.

TIMING

SW5, SW8 & SW10

- Set to 106 to 108 degrees full lift #1 inlet. Tappet 0.015" inlet/exhaust.

SW23

- Set to 101 full lift #1 inlet. Tappets 0.016 inlet/exhaust.

These figures have been ascertaned from our dyno development and have been given best results in this window.

FITTING

- 99% of camshaft failures occur from dirty assembly. Make sure your block is clean in all oil ways. Thoroughly wash the camshaft and followers with cleaning fluid as the products are protected with anti-rust coating.

- Check you camshaft bearings are in good condition, or re-new them.

- Always prime oil pump with new oil before fitting.

- Swiftune double valve spring fitted length... Road 1.380" | Race 1.400"

- Note: A+ timing cases will need the small dent knocking out the breather shield cutting and knocking flat when fitting Duplex set.